Located in Heidelberg, the Wave House is designed to be a new data center in the urban heart of Germany. Designed by SSV and Mense Korte, and built by Peri 3D Construction for the developer KrausGruppe, the Wave House was 3D-printed, adding an element of style and personality to the rather mundane arena of cloud-computing infrastructure. The end result is Europe’s largest 3D-printed building! The building measures 6600 sq ft and has a rather unique appearance, in an attempt to draw attention and make it unlike the typical 3D-printed structures we come across.

Designer: SSV, Mense Korte & Peri 3D Construction

“Due to the typical absence of windows and large openings in all or the main areas of data centers, for safety and other reasons, data centers tend to look quite dull and uninspiring,” said a press release by COBOD. “As long as such data centers are placed far outside the cities this problem is perhaps of less concern, but the trend towards making data centers more in the vicinity of the users and therefore locate them in suburban areas and cities has created a need to make the data centers more visually appealing.

This issue was resolved by imparting the walls with an innovative wave design, which also lends the building its name. The fascinating waves could not have been built using traditional construction methods, hence 3D-printed technology was adopted, to support creative and design freedom while producing the walls.

The construction process of the Wave House is similar to other 3D-printed projects we’ve come across. It was printed using a single COBOD BOD2 printer, the same model that has been utilized to build other 3D-printed buildings of importance. The printer extrudes a recyclable cement-like mixture in layers via a nozzle. This is done at a rate of 43 sq ft per hour to create the exterior walls which have a length of 177 ft, a width of 35 ft, and a height of 29.5 ft.

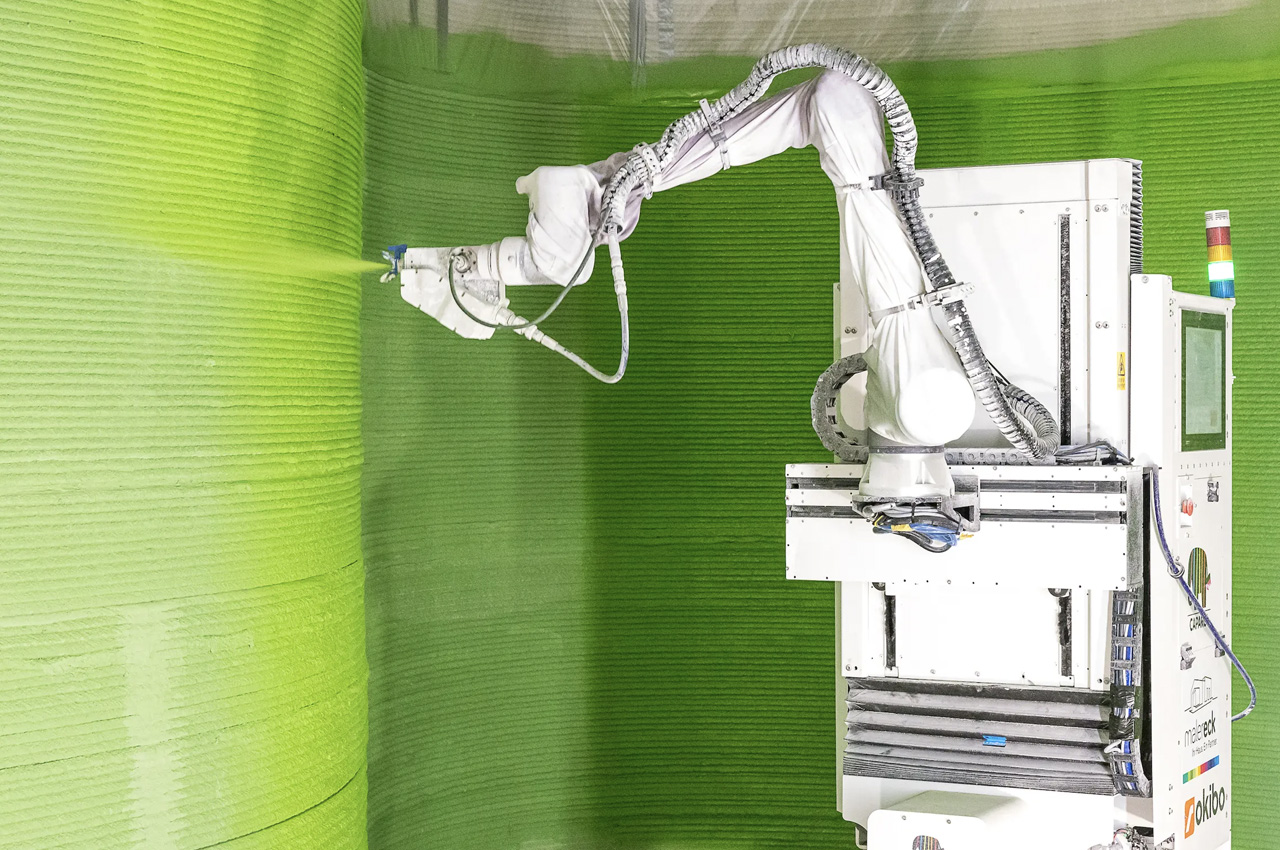

The entire printing process involved around 140 hours, after which, finishing touches were added to the project by humans. These touches include the doors, roof, lighting, as well as the wiring and gear needed for a data center well-connected to the internet. A robotic painter by Deutsche Amphibolin-Werke was utilized to paint the interiors of the building. How cool!